Description

Automatic Feeding Nut Riveting machine Application video

Equipment Introduction

AU500 is a high-performance riveting system that integrates advanced blind riveting tool functionality with an automatic rivet nut feeding mechanism This tool system supports a wide range of rivet nuts from M4 to M10, featuring full automation and high reliability It is well-suited for industrial large-scale production scenarios, capable of achieving an installation efficiency of 20-30 rivet nuts per minute in most applications

Equipment Specifications

Model: AU500

Rivet Nut Size:M4 To M10

Operating Voltage:6~8Kg/cm²(0.6~0.8MPa)

Rated Power:200W

Nut Capacity:1000PCS

Maximum Feed Rate: 20-30 pcs/min

Weight: 40-45KG

Input Power: AC220V 60/50HZ

Rivet Feeding Distance:2.5M~3M

Equipment Size:550*380*355MM(L*W*H)

Machine Details

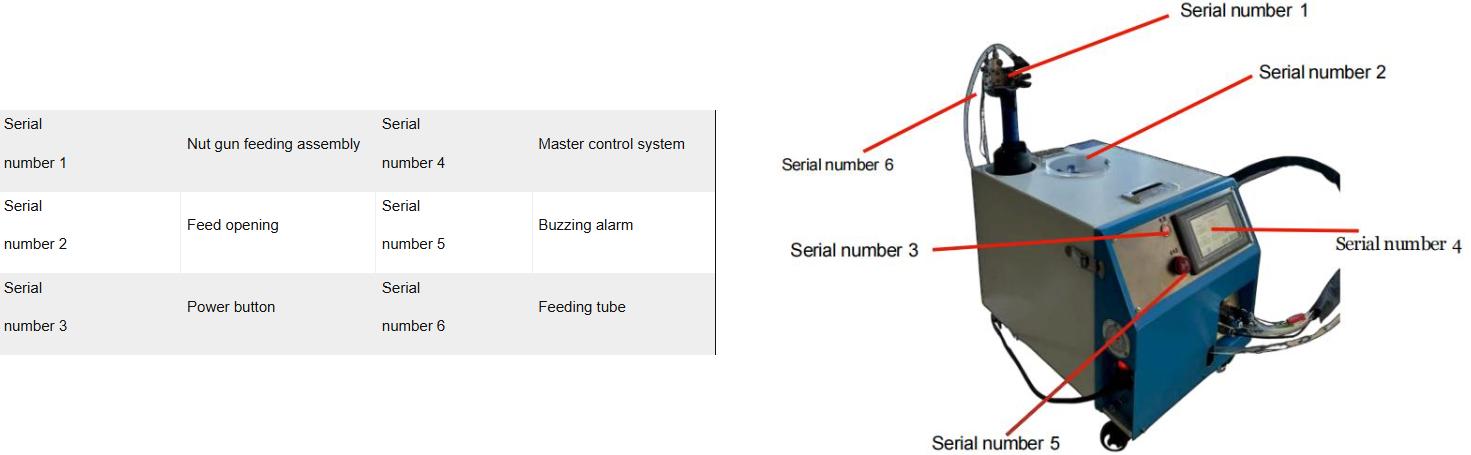

The nut automatic riveting machine mainly consists of three major systems:

1. Automatic Feeding System: Responsible for the automated feeding of rivets

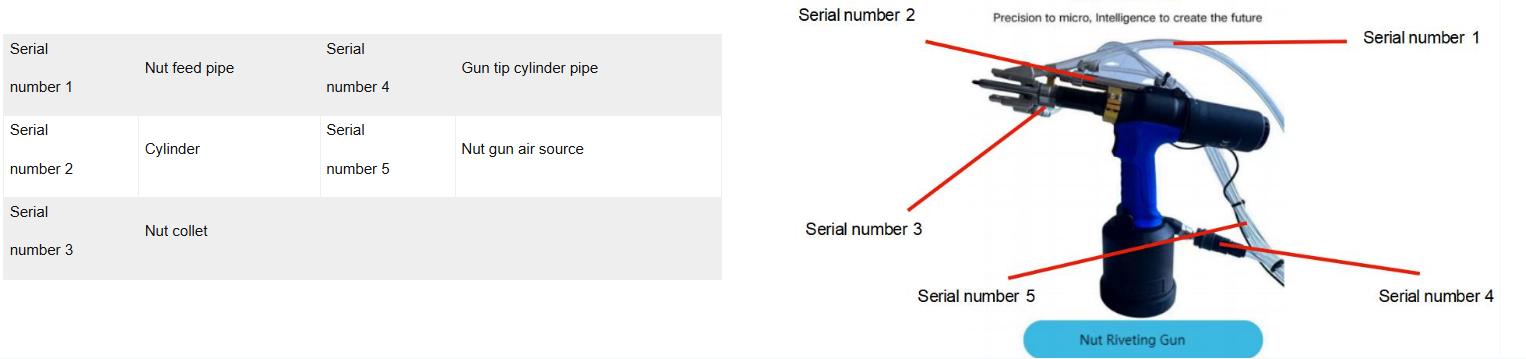

2. Riveting System: Handles the automatic feeding of nuts to the gun head mechanism followed by the riveting process

3. PLC Control System: Manages and regulates all motion parameters of the entire system

How to use the machine?

Machine Operation Instructions:

1. Initial Startup: After starting the machine, pull the nut gun trigger to automatically feed a nut into the gun for riveting.2. Operation Cycle: After completing riveting, move the gun head approximately 100mm away from the product surface before releasing the trigger to initiate the next nut feeding cycle.

3. Emergency Protocol: In case of gun head jamming or other malfunctions during operation, immediately press the emergency stop button on the control panel before troubleshooting.