Description

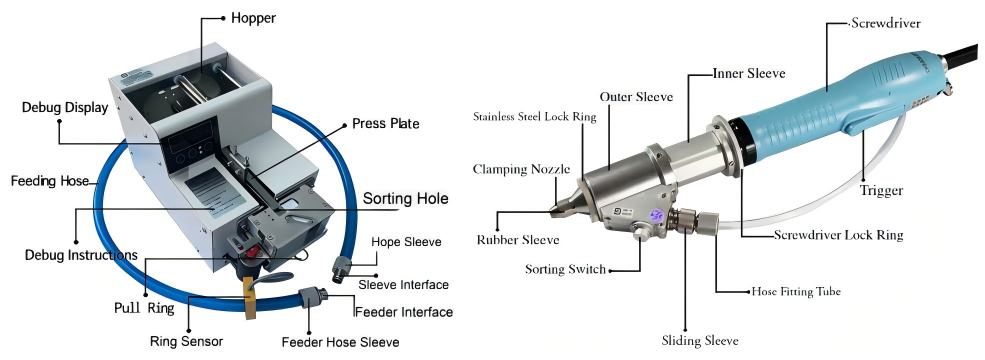

Machine Description

This gravity drop-type automatic screw feeder with a handheld fastening tool is a high-performance portable semi-automatic screw driving device that perfectly integrates high operational efficiency with outstanding cost-effectiveness. Featured with automatic screw feeding, precise sorting and rapid screw fastening functions, this equipment enables effortless one-handed operation for flexible and convenient use in various working scenarios. After putting this handheld screw fastening machine into production, a single operator can achieve work efficiency equivalent to three manual assemblers, which remarkably boosts factory production output while substantially cutting down labor costs.

Technical Parameters

Applicable screw specification: M1.0-M6.0 (One machine for one screw specification, non-universal type)

Applicable screw length: 2.7-25mm

Applicable screw head diameter: 1.9-12mm

Applicable screw size ratio: The ratio of screw head diameter to screw shank length is 1:1.2

Feeding mode: Electric gravity drop type

Usable screw locking hole depth: 0-40mm (Optional configuration)

Applicable screw shape: No limitation

Applicable screw material: No limitation

Working power supply: Input 100-240V~50/60Hz 1-2A; Output 12-15V 1-3A

Working efficiency: 50-70PCS/MIN (Depending on the screw length)

Power: 50W; Noise: ≤ 50 dB

Screw conveying distance: 1-2 meters

Screw hopper capacity: 1000 pcs for standard M3*8 screws

Feeding speed: 80-120 pcs/min

Electric screwdriver: Adjustable torque, adjustable rotating speed 0-1800 r/min

Locking mode: Electric screwdriver

Overall dimension: L26cm * W14.5cm * H14.6cm

Net weight: Feeder 3.4kg, Electric screwdriver 0.75kg

The Machine Details And Operation Method

When the screws enter the blanking tube and fill it up through the orbital vibration of the gravity type automatic screw feeder with handheld screw fastening gun , the screw fastening and locking operation can be started. For the first screw locking operation, press the handheld electric screwdriver once first to deliver the first screw to the stainless steel nozzle. Then align the stainless steel nozzle (collet nozzle) with the hole requiring screw locking, press down the electric screwdriver and activate the switch button of the electric screwdriver. Lift up the electric screwdriver after hearing the sound of the electric screwdriver completing the screw locking with automatic brake, and the single screw locking is finished. Then continue to lock and fasten the next screw in sequence for continuous operation.

Important Notes:

① Do not press the start button of the electric screwdriver again before the previous screw is completely locked and fastened, so as to avoid the jamming fault caused by two screws stuck in the collet nozzle of the bit holder!

② Keep the handheld electric screwdriver in a vertical state as much as possible during the screw locking operation, to prevent the screw from deviating from the hole position and affecting the screw locking and fastening effect.

Machine Features

Efficient Drop-type Feeding System

Adopts a gravity-driven drop feeding mechanism that delivers screws directly to the screwdriver bit one by one without manual alignment. It eliminates the need for operators to pick and place screws manually, cutting down on assembly time and boosting work efficiency by 50%–80% compared with traditional manual screwing

Handheld Ergonomic Design

Light weight and compact body with a non-slip grip handle, designed to reduce hand fatigue during long hours of operation. The balanced weight distribution ensures comfortable handling for both vertical and horizontal assembly tasks, suitable for small-scale workshops or on-site maintenance work.

Precise Screw Positioning

This Drop-type Automatic Screw Feeder and Handheld Fastening Machine is equipped with a spiral guiding channel, which can stabilize the screws during the tightening process and prevent any skewing or sliding during the fastening. This feature ensures the uniform application of torque and avoids damage to the workpiece or the threads, and is particularly suitable for the assembly of precision electronic products.

Low Fault Rate & Easy Maintenance

The drop-type feeding structure has fewer moving parts than vibration-type feeders, which means lower wear and tear and fewer jamming issues. The detachable feeding module allows quick cleaning and part replacement without professional tools, reducing downtime for maintenance.

Flexible Application Scenarios

Unlike bench-top automatic screwdrivers, this handheld model offers high mobility. It can be used for assembling large workpieces (e.g., household appliances, furniture) that are not easy to move, as well as for batch assembly of small components on production lines.

Other Related Equipment You May Need

|

|

|

|