Description

Product Description

As a core feeding module for automation equipment, the step screw feeder can seamlessly connect to production lines in electronic manufacturing, auto parts assembly and other industries. It reduces manual intervention and enhances production continuity.

1. For the stepped-type feeding system with the characteristics of small screws and capacity, screws can be discharged smoothly.

2. The screw outlet sorting adopts cylinder transmission, and the number of screw pipes can be independently switched. The blanking belt is equipped with an annular detection switch to identify whether the screw enters the progress pipe.

3. The whole screw machine adopts direct-vibration transmission, uses AirTAC or SMC pneumatic components, and the system adopts an all-in-one touch machine.

4. Touch-screen window functions: screw channel selection, screw counting, vibration debugging, feeding speed, feeding delay, vibration delay, blowing time, etc.

5. Provide external signal lines, start signal, completion signal, and alarm signal.

6. For the material distribution at the screw outlet, a screw rod + motor transmission or cylinder transmission is adopted. The number of screw-discharging pipes can be independently switched. The blanking belt is equipped with an annular detection switch to identify whether the screw enters the pipeline.

7. The blowing screw machine as a whole adopts direct-vibration transmission, with AirTAC or SMC pneumatic components, and the system adopts an all-in-one touch machine.

8 Functions of the touch-screen window: screw channel selection, screw counting, vibration debugging, feeding speed, feeding delay, vibration delay, blowing time, etc.

9. Provide external signal lines, start signal, completion signal, and alarm signal.

Machine Parameters

|

Model |

AS-120 |

AS-180 |

|

Dimensions |

200*W251*H330mm |

L300*W400*H383mm |

|

Weight |

15KG |

30KG |

|

Input voltage |

AC100V-240V (50/60HZ) |

AC100V-240V (50/60HZ) |

|

Output voltage |

DC24V |

DC24V |

| Applicable screws | M1.4-M4.0mm, Total screw length>1.3 times of cap diameter, total length<25mm | M2-M6mm, Total screw length>1.3 times of cap diameter, total length<50mm |

|

Line protection |

Overload shutdown |

Overload shutdown |

|

Feeding speed |

50 to 100 pieces per minute | 50 to 100 pieces per minute |

|

Failure rate |

Within 3 PCS per 10,000 |

Within 3 PCS per 10,000 |

|

Feeding hose |

3-10 meters |

3-10 meters |

|

Screw capacity |

1.2L |

2L |

| Loading method | Step push type | Step push type |

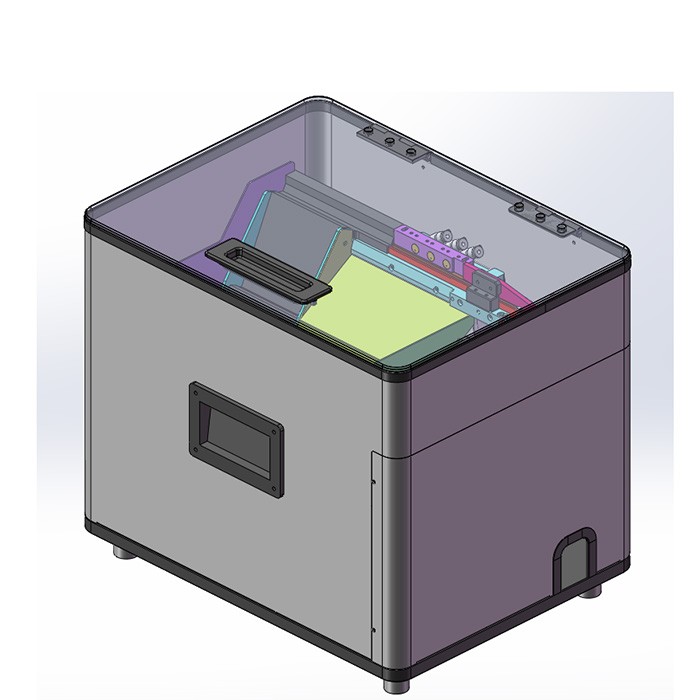

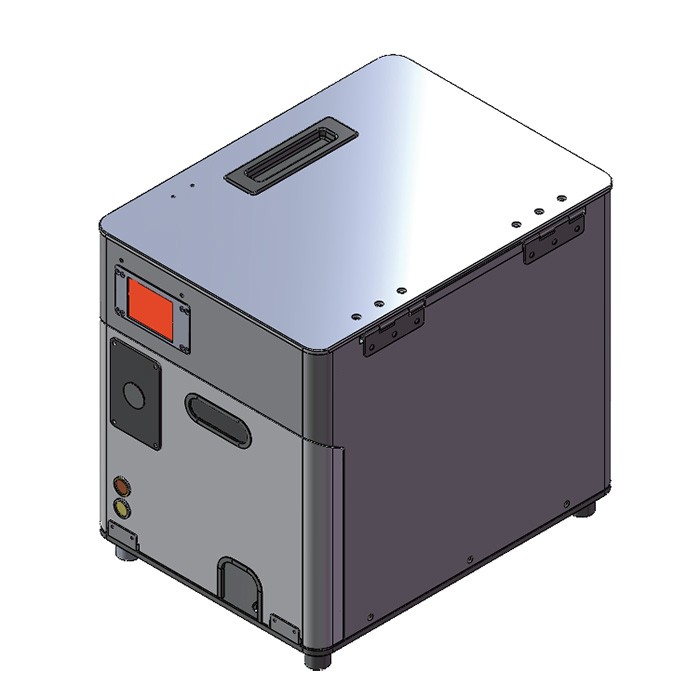

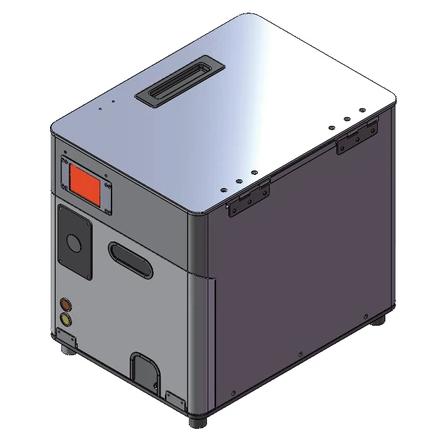

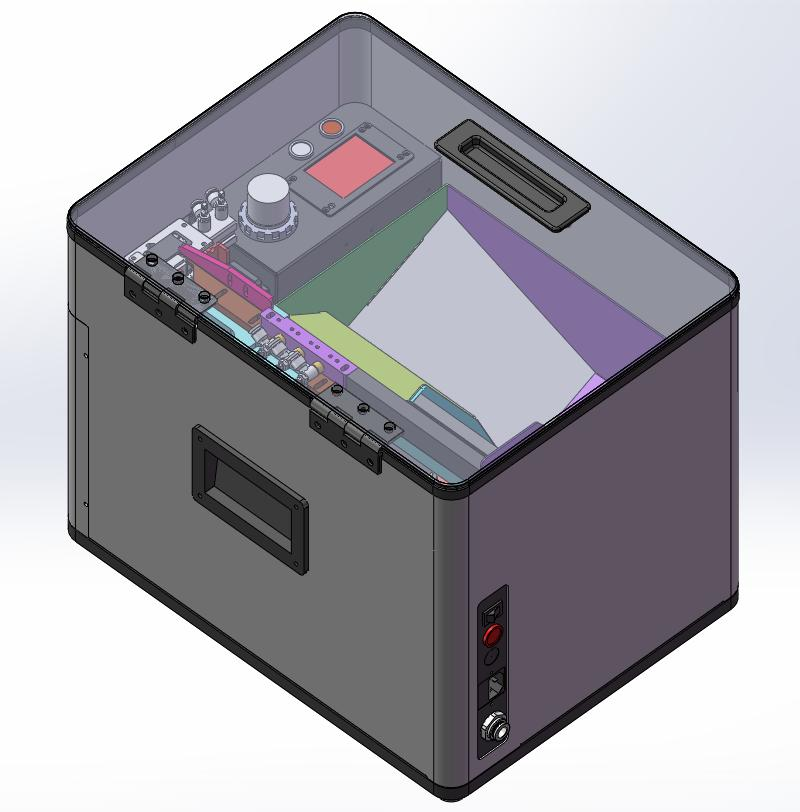

Machine Display

Machine Features

1. Utilizing a PLC integrated touch machine, it is applicable to M2 - M6 screws with a length within 50mm.

2. For clean feeding, the hopper has no vibration source, resulting in less friction with the screws. It is not prone to generating debris and causes minimal damage to the screw surface, enabling clean-type feeding.

3. The low nail jamming rate is achieved as the mechanical structures of the stepped feeding, V-shaped pushing track, feeding track, and dispenser have been newly upgraded, significantly reducing the probability of nail jamming.

4. Optional accessories include an electric door lock, cleaning module, long and short nail detection module, and supplementary bin.

5. Multi-channel management is supported, enabling screw channel selection and rapid switching through IO commands.

6. Diversification is realized by supporting the feeding of bolts, rivets, nuts, and pins. It is designed according to workpieces for stable output.